How it turned from hobby to a family business

Since 2015 Ventsar family production facility has been producing steel baking tins and baking moulds in a plenty of types and sizes. The creator, main inspirer and one of top managers Aleksandra Belyak tells the story how hobby turned into a business enterprise.

«Our business startup is closely linked with our family. When I was pregnant with my second baby, I went to a pastry school of an amazing pastry chef Yuliya Stovbun: I wanted to learn the entire secrets of how to bake tasty and beautiful cakes. During the studies, I required a round baking tin of a particular special size for making a chiffon cake. I asked my husband to produce it for me. At that time my husband Valera had an air ventilation system company and a workshop with different machines and tools. He made me a round baking tin, I brought it into my class and all the Ladies claimed they wanted to have the same round baking tins! This was a starting point. Today my husband is a Head of the production department: he is a very broad-minded and talented person. He finished artistic-graphic faculty as a descriptive geometry teacher. Therefore, he is responsible for a creative and operational parts of the process. Yuliya Stovbun became not only my first teacher and inspirer, but a close family friend. Moreover, now we produce baking tins for her pastry-shop.

I cannot say it was easy to begin. At first, we made a page at "Classmates" social network with only 10 followers. Little by little, more and more confectioners learned about us, later on bigger baker's shops showed their interest towards us. As for now, we receive the Orders from abroad and have already arrange deliveries to Germany, Canada, and Cyprus. Confectioners from the other countries appreciated the quality of our baking tins, which is never lower than the quality of Italian baking tins. They say it's hardly possible to find abroad any baking tins with height 15-20 cm. We are the ones who produce such baking tins

We do care about both small and huge Orders on the same level. Every our Client is special, so the size of the Order does not matter for us. We always guarantee high quality and attentiveness on every stage of work. We strictly abide by the timeframes indicated by our Clients. For example, one of our Clients was beyond the deadlines of making a cake and a baking tin was required ASAP. It took us about 1 hour to produce the required baking tin and send it to our Client by taxi. The dessert was done in time, "Pigeon's milk" was perfectly filled in the baking tin, then rested and the steel withstood the temperature changes brilliantly.

It is extremely important for us to receive our Clients' feedbacks. I personally control the packing and shipping process of all Orders, track the delivery step by step and can update our Client with each stage of the delivery. Afterwards I contact our Clients to know if they are satisfied with the delivered Item. Our Clients usually provide us with their reviews about the tin shape, send the photos of their desserts, share their stories, thoughts and ideas. It definitely helps us to improve. For example, once one of our Clients requested a discount for a baking tin to take part in the charity event called "Sweet Goodness". Caring confectioners take part in this event to support disabled children or children with developmental issues by baking cakes for them. As a mother of 3 kids I couldn’t stand behind and sent our Client a baking tin for free. Such cases are really touching and inspiring. Quite often business relations transfer into a real friendship and it worths to work for it!"

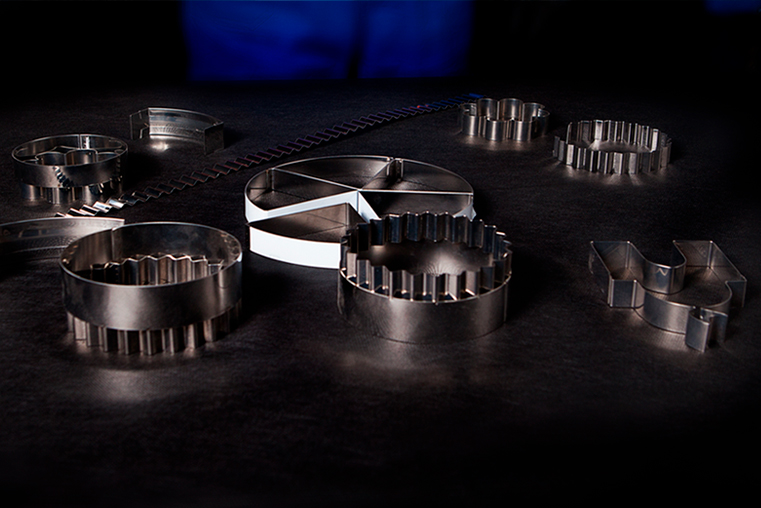

The examples of the baking tins we produced, your ideas will be highly appreciated

Ventsar facility

Ventsar facility is equipped with a great variety of different machines and tools, therefore we can offer you a plenty of different sizes : from the smallest cuts for the sugar flowers to the round baking tins for huge Surprise Cakes or Chandelier Cakes with 1 meter or more in diameter. Both machine and manual labor are used in the production of baking tins. All stages are controlled by the Head of the company - Valeriy Sarygin. The facility operates in two shifts to be able to meet all deadlines. The most relevant thing is that Ventsar employees do care about the results and wait for the positive feedbacks from the Clients, because they work hard and put all their skills to help you to create your baking masterpieces.